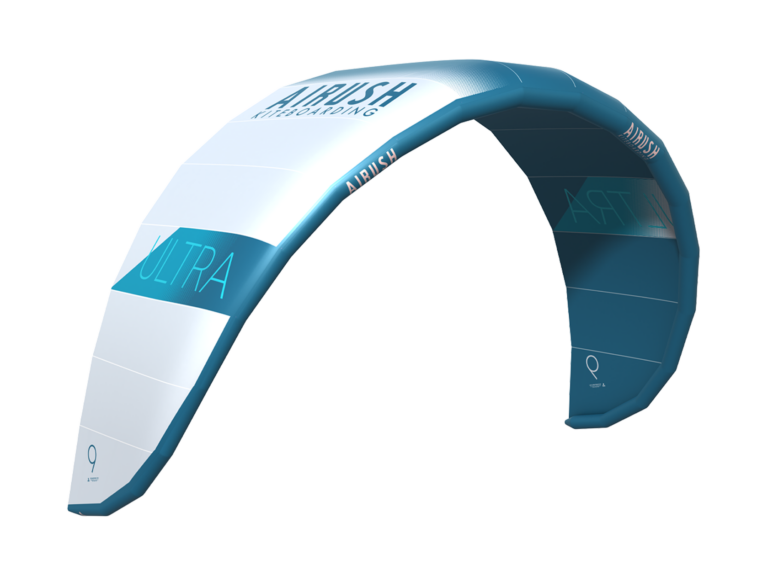

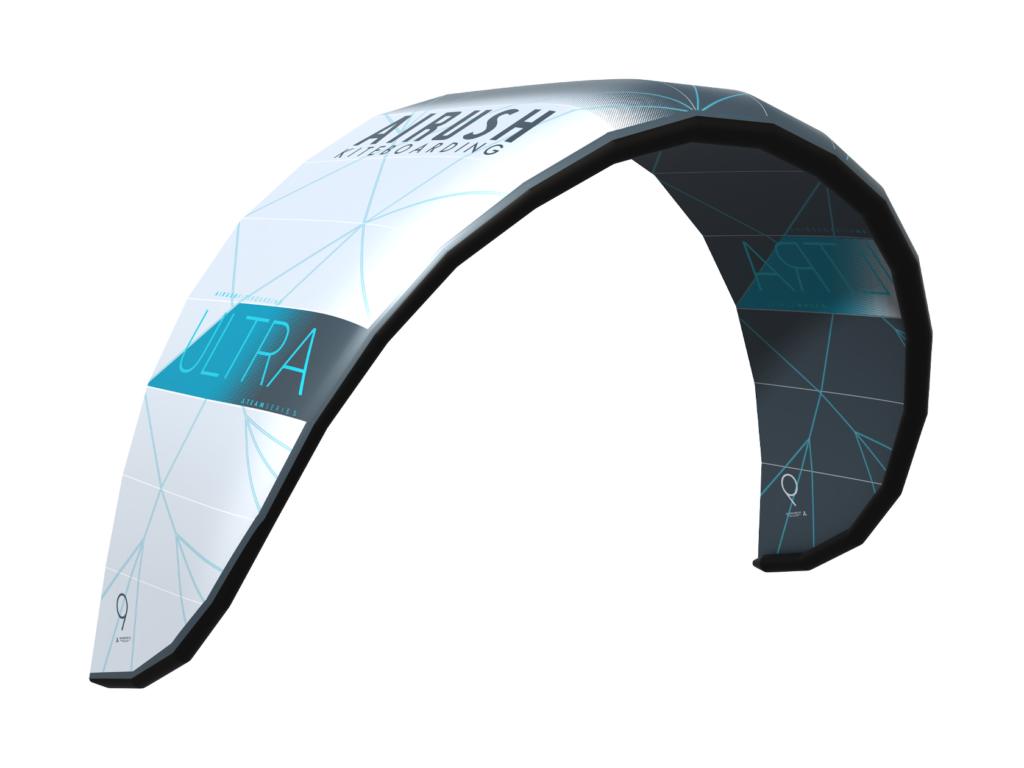

ULTRA TEAM KITE

Version 5

Sizes: 7, 8, 9, 10, 12, 14, 17m

The Ultra Team features the Airush Team Series construction.

Ho’okipa is a material technology that allows the kite to find an optimal balance between responsiveness, lightweight, and long term performance. Ho’okipa is made of Ultra PE fibers that makes the leading edge 10x stronger and stiffer than traditional fabrics.

The combination of our proven Single Strut Geometry, with the new narrow diameter high pressure leading edge and high-tension canopy is key; this is what allows the Ultra Team to fly forward in the window, creating the perfect balance for lightwind performance.

KITE PERFORMANCE

| KITE SIZE | KITE WEIGHT (KG) | WIND RANGE (Knots) | BAR LENGTH | RIDER WEIGHT |

|---|---|---|---|---|

| 7m | 1.69 | 15 - 30 | 50cm | 75kg Avg. |

| 8m | 1.88 | 14 - 29 | 50cm | 75kg Avg. |

| 9m | 1.98 | 13 - 28 | 50cm | 75kg Avg. |

| 10m | 2.12 | 12 - 25 | 50cm | 75kg Avg. |

| 12m | 2.39 | 10 - 22 | 50 - 60cm | 75kg Avg. |

| 14m | 2.62 | 7 - 18 | 50 - 60cm | 75kg Avg. |

| 17m | 3.09 | 6 - 16 | 50 - 60cm | 75kg Avg. |

REVIEWS

WATCH VIDEO

KITE PERSONALITY

The Ultra Team is a more responsive, faster, and lighter version of the Ultra reinforced with Ho’okipa Ultra PE material.

KITE TECHNOLOGY

The Airush Load Frame has been the key to setting the ultimate benchmark in durability without compromising on weight. Ultra-high modulus yarns carry the primary load of the canopy, preventing stretch, and increasing long-term performance. The Load Frame is further enhanced by WebTech which is featured in the areas traditionally occupied by Dacron. This enables us to minimize or completely remove the heavier fabric and utilize the ballistic high-modulus web fibers instead – increasing strength and minimizing weight.

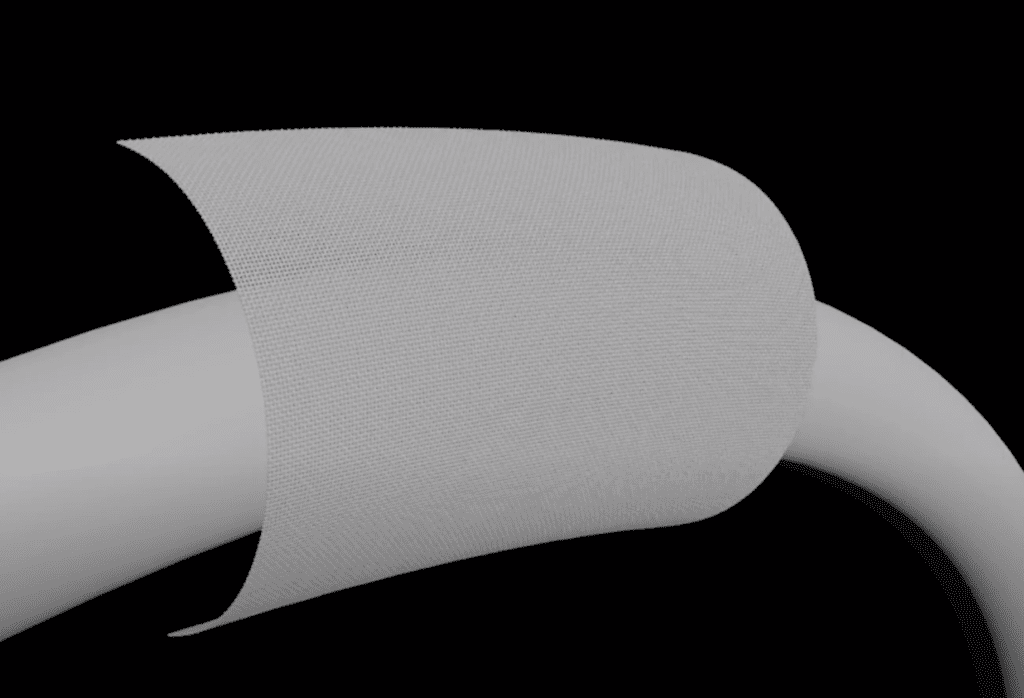

WebTech minimizes or replaces the traditional Dacron reinforcement by channeling the broader loads into the Load Frame through a web ‘subframe’ of ultra-high molecular polyethylene (ultra-high modulus). This is featured in key areas such as the primary attachment points on the leading edge or the rear attachment points, while also being used to support structural components such as the center strut.

Developed in partnership with Challenge Sailcloth, this unique Ultra PE leading edge composite material is 25% lighter and 10x stronger than traditional fabrics. This allows for 50% higher pressure, creating increased stiffness combined with a thinner leading edge. The result is supercharged responsiveness coupled with sublime handling, and of course the long-term performance you expect from Airush.

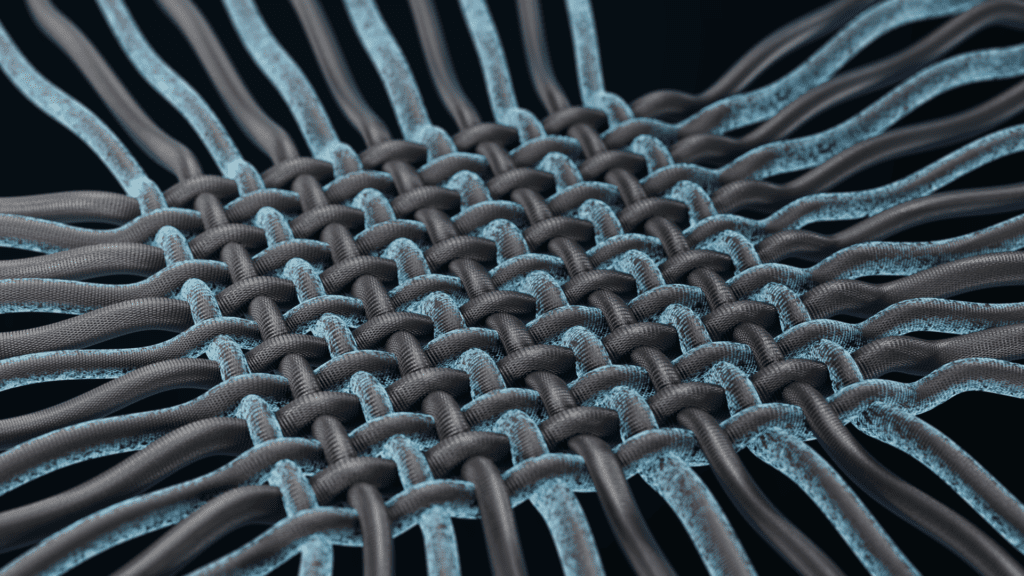

UHMWPE fibers (non-branded Dyneema® or Spectra®) are the lightest and strongest fibers commercially available, with a tensile strength 15x stronger than steel. UHWMPE is created by a gel-spun extrusion process which draws out extremely long chains of polyethylene, aligned along a molecular backbone. This alignment effectively transfers load through the fiber for high modulus and strength.

LIGHT YEARS AHEAD

Ultra Team Kite

Version 5

Team engineered lightweight design for foil, freeride & surf.

Reduced diameter leading edge for maximum efficiency.

Ho’okipa Ultra PE high pressure leading edge & Load Frame.

Available Sizes: 7, 8, 9, 10, 12, 14, 17m

KITE PERFORMANCE

DESCRIPTION

The Ultra Team features Ho’okipa, which is a material technology that allows the kite to find the optimal balance between responsiveness, lightweight, and long team performance.

Ho’okipa is made of Ultra PE fibers that make the leading edge 10x stronger and stiffer than traditional fabrics. The combination of our proven Single Strut Geometry, with the new narrow diameter high pressure leading edge and high-tension canopy is key; this is what allows the Ultra Team to fly forward in the window, creating the perfect balance for lightwind performance.

KITE PERSONALITY

The Ultra Team is a more responsive, faster, and lighter version of the Ultra reinforced with Ho’okipa Ultra PE material.

| KITE SIZE | KITE WEIGHT (KG) | WIND RANGE (Knots) | BAR LENGTH | RIDER WEIGHT |

|---|---|---|---|---|

| 7m | 1.69 | 15 - 30 | 50cm | 75kg Avg. |

| 8m | 1.88 | 14 - 29 | 50cm | 75kg Avg. |

| 9m | 1.98 | 13 - 28 | 50cm | 75kg Avg. |

| 10m | 2.12 | 12 - 25 | 50cm | 75kg Avg. |

| 12m | 2.39 | 10 - 22 | 50 - 60cm | 75kg Avg. |

| 14m | 2.62 | 7 - 18 | 50 - 60cm | 75kg Avg. |

| 17m | 3.09 | 6 - 16 | 50 - 60cm | 75kg Avg. |

KITE TECHNOLOGY

The Airush Load Frame has been the key to setting the ultimate benchmark in durability without compromising on weight. Ultra-high modulus yarns carry the primary load of the canopy, preventing stretch, and increasing long-term performance. The Load Frame is further enhanced by WebTech which is featured in the areas traditionally occupied by Dacron. This enables us to minimize or completely remove the heavier fabric and utilize the ballistic high-modulus web fibers instead – increasing strength and minimizing weight.

WebTech minimizes or replaces the traditional Dacron reinforcement by channeling the broader loads into the Load Frame through a web ‘subframe’ of ultra-high molecular polyethylene (ultra-high modulus). This is featured in key areas such as the primary attachment points on the leading edge or the rear attachment points, while also being used to support structural components such as the center strut.

Developed in partnership with Challenge Sailcloth, this unique Ultra PE leading edge composite material is 25% lighter and 10x stronger than traditional fabrics. This allows for 50% higher pressure, creating increased stiffness combined with a thinner leading edge. The result is supercharged responsiveness coupled with sublime handling, and of course the long-term performance you expect from Airush.

UHMWPE fibers (non-branded Dyneema® or Spectra®) are the lightest and strongest fibers commercially available, with a tensile strength 15x stronger than steel. UHWMPE is created by a gel-spun extrusion process which draws out extremely long chains of polyethylene, aligned along a molecular backbone. This alignment effectively transfers load through the fiber for high modulus and strength.

GALLERY

TECH VIDEO

BUILD YOUR QUIVER

ULTIMATE LIGHTWIND GEAR

AIRUSH ULTRA TEAM KITE REVIEWS

Available sizes: 5, 6, 7, 8, 9, 10, 12, 14, 17m

Ultra Team Kite

Team engineered lightweight design for foil, freeride & surf.

Reduced diameter leading edge for maximum efficiency.

Ho’okipa Ultra PE high pressure leading edge, strut & load frame.

Defining the future of minimalistic, lightweight performance design for foil, freeride, and surf, the Ultra Team is a more responsive, faster, and lighter version of the Ultra reinforced with Ho’okipa Ultra PE material. Featuring a thinner, higher pressure leading edge to reduce drag and allow for a higher angle of attack when riding upwind, as well as a fixed bridle for direct steering. The unique blend of efficiency, stability and responsiveness creates an extremely versatile product.

KEY FEATURESLightweight single strut geometry

Improved canopy tension & rigidity to increase responsiveness

Fixed bridles

Ho’okipa LE narrower diameter

LE high pressure Ultra PE leading edge and struts

Ultra PE Airush Load Frame v4 featuring WebTech

Higher tension LE and strut

Reduced weight

ULTRA TEAM BRIDLE OPTIONS

All Ultra Team kites are shipped with a Fixed Bridle.

The 12m, 14m and 17m Kites are shipped with a Fixed Bridle and 3V pulley bridle.

The fixed bridle is the preferred choice for this product for the following reasons:

- Lighter weight

- More direct feel

- More responsive when piloted proficiently with great on/off power control.

Reasons for including a 3-V pulley bridle in the larger sizes 12m, 14m and 17m:

- More traditional Ultra V4 feel with the added performance benefit of lightweight kites

increased user-friendliness at the top end of the kite’s wind range due to consistent back line tension even when de-powered. For overpowered riding on the big sizes, the pulley bridle adds slightly more depower and control when depowered.

The V3 Pulley bridle option is recommended for:

- Beginner to Intermediate riders who are looking for a lighter-weight Ultra kite.

- For advanced riders going out in gusty or changeable conditions where the wind picks up to out of the kite’s recommended wind range quickly.

Gallery

KITE TECHNOLOGY

Running up to 50% more leading edge pressure, this creates a stiffer structure and ultimately allows us to run a thinner leading edge.

The biggest combined benefit of the Ultra PE is the ability to run high tension without sacrificing longevity. This higher tension leading edge and strut creates a much more responsive frame that responds quickly to rider input and keeps the kite stable.

The Airush Load Frame, featuring WebTech, has been the key to setting the ultimate benchmark in durability without compromising on weight.

By expanding our exclusive Load Frame with WebTech throughout the areas normally occupied by Dacron, we are able to minimize or completely remove the heavier fabric, and utilize the ballistic high-modulus polyethylene web fibers instead – increasing strength and minimizing weight.

Utilizing the same Ultra PE primary fiber as the leading edge and struts, the load frame carries much of the primarily load running through the canopy. This prevents the canopy cloth from over stretching and losing performance. This also increases responsiveness by creating a more locked in shaping into the canopy.

Reduces the drag on the kite, allowing a higher angle of attack when going up wind, or travelling at higher speed. Important in more offshore wave conditions to help keep the rider on the wave face.

Featuring swept wingtips for instant relaunch.

Featuring fixed bridles for a more direct & responsive feel.

The Ho’okipa Ultra PE fabric is 25% lighter than traditional Dacron leading edge materials. The reduced diameter structures and optimized details, result in an overall weight saving of up to 30%. The reduced weight keeps the Ultra Team flying even in the lightest conditions.

Ho'okipa Ultra PE

Developed in partnership with Challenge Sailcloth, this unique Ultra PE leading edge and strut composite material is 25% lighter and 10x stronger than traditional fabrics. This allows for 50% higher pressure, creating increased stiffness combined with a thinner leading edge. The result is supercharged responsiveness coupled with sublime handling, and of course the long-term performance you expect from Airush.

UHMWPE fibers (non-branded Dyneema® or Spectra®) are the lightest and strongest fibers commercially available, with a tensile strength 15x stronger than steel. UHWMPE is created by a gel-spun extrusion process which draws out extremely long chains of polyethylene, aligned along a molecular backbone. This alignment effectively transfers load through the fiber for high modulus and strength.

KITE PERFORMANCE

reviews

SPECIFICATIONS

Tech Video

Kite Details

When it comes to defining the future of lightweight performance design for foil, freeride, and surf, we introduce the new Ultra Team, featuring Ho’okipa.

Conceived as the ultimate kite for the minimalist, the single strut Ultra continues to lead the revolution of foil and light-wind freeride. From this incredible base, we have developed the Ultra Team, the result is supercharged responsiveness coupled with sublime handling, and of course the long-term performance you expect from Airush.

Developed in partnership with Challenge Sailcloth, the Hoókipa Ultra PE leading edge and strut composite material is 25% lighter and 10x stronger than traditional fabrics. This allows for 50% higher pressure, creating increased stiffness combined with a thinner leading edge.

As a base material Ultra PE up to 32 x stronger compared directly to polyester, with the Ultra PE fiber being 15x stronger than steel at the same weight and 2x lighter than Carbon Fiber, in fact Ultra PE fiber is so light that it floats on water. Once integrated into Hoókipa´s unique woven structure, a high amount of material in the composite is structural, allowing us to optimize all areas of the construction.

Understanding the characteristics of this material is the key to the responsiveness of the Ultra Team – the process of inflation places a higher tension on the stiff fabric and you feel that immediately. The biggest combined benefit of the Ho´okipa is the ability to run high tension without sacrificing longevity. This higher tension leading edge and strut creates a much more responsive frame that responds quickly to rider input and keeps the kite stable.

Running up to 50% more leading-edge pressure, this creates a stiffer structure and ultimately allows us to run a reduced diameter high pressure leading edge and struts. The thinner LE reduces the drag on the kite, allowing a higher angle of attack when going upwind, or traveling at a higher speed. Which is also ideal in more offshore wave conditions to help keep the rider on the wave face.

Utilizing the same Ultra PE primary fiber as the leading edge and struts, the load frame carries much of the primary load running through the canopy.

Hookipa Ultra PE fabric is 25% lighter than traditional Dacron leading-edge materials. With the 5m weighing in at under 1.5kgs, this is the lightest production 5m we have ever made and this reduced weight keeps the kite flying even in the lightest conditions.

Considering how small the Ultra Team packs down, its reduced weight, and crazy low end, it will become your ultimate travel partner.

When it comes to finding the future of lightweight performance design for foil, freeride,

and surf, look no further than the Ultra Team.